CPE Technology

Our state-of-the-art plant uses world renowned CPE Technology acquired through technical know-how from German giant MANNESMANN DEMAG HUTTENTECHNIK Gmbh.

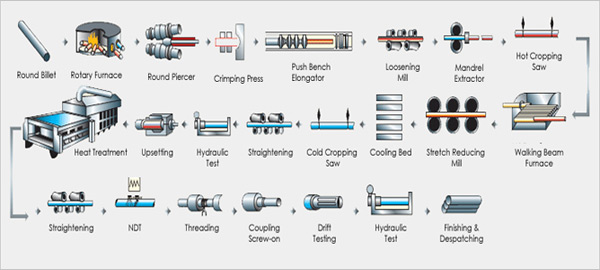

The CPE (Cross Roll Piercing and Elongation) process begins with the piercing of a hot billet on the piercer, followed by crimping and then elongation on the push-bench and finally the dimensions are controlled within specified variation on the Stretch Reducing Mill (SRM).

This process minimises longitudinal and transverse defects in pipes and tubes. It also ensures better control over wall thickness variation as compared to other manufacturing processes.

CPE Process