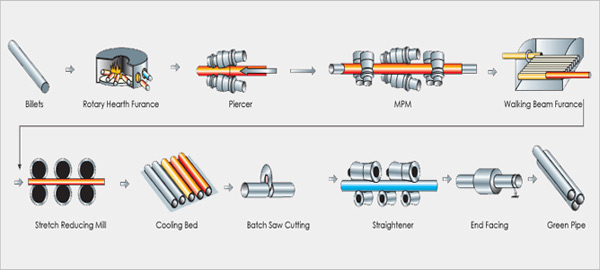

MPM Technology

MPM is the State-of-the-art manufacturing process for high Quality Seamless Pipes and Tubes. In this Process pierced hollow is further elongated by 6 stand continuous rolling mill, where a high precision mandrel inside the hollow moves along with pipe during rolling, which ensures smooth internal surface finish of the pipe.

Each stand is equipped with Hydraulic gauge control, which ensures uniform thickness throughout the length. The deformation of hot metal is in longitudinal direction, which gives better mechanical properties and no torsional stress is induced during hot rolling, which ensures defect free product.

MPM Process